The process of rapid prototyping is changing how large corporations develop customized PCB solutions.

Did you know that the rapid prototyping industry will experience considerable growth by 2031 and be valued at around $32.4 billion (Source: Transparency Market Research)?

This is because there has been an increased need for quicker and cheaper product development cycles.

The fast customization of Printed Circuit Manufacturing is very important for big companies who wish to create their own niche and stay competitive in today’s market.

This has made rapid prototyping a game-changer across all industries, as it supports them in creating physical prototypes from digital designs much more quickly than before.

Let’s know how rapid prototyping is changing the manufacturing process of custom PCBs.

What is Rapid Prototyping for PCB Solutions?

Consider rapid prototyping as a test drive for your PCB (printed circuit board) solutions. Make a quick model of your circuit board to experiment with your ideas before you start making them in bulk.

Rapid prototyping will allow your technical team to identify initial issues and resolve them. Consequently, you don’t have to create the final product for testing and save money.

You will be able to start implementing the project sooner because you do not have to wait an eternity until you see the design in action. It is very helpful for large corporations requiring the right functioning custom PCBs at once.

Reverse engineering is another important aspect of New product ideas. Many companies search for Reverse Engineering of PCB Circuitry to improve existing products or introduce new products.

A glance at PCB Development Challenges

Custom PCB development for large enterprises comes with several challenges. One of the main problems is ensuring that the design coincides exactly with specifications, as any deviation may lead to inefficiencies or system failures.

It takes a lot of time to develop, and rapid prototyping is important in order to guarantee timely delivery.

Also, modern technology demands that circuit boards be more complex than ever before, yet they retain small sizes without compromising performance.

This means that rapid prototyping becomes a critical step toward the successful and dependable manufacturing of printed circuit boards (PCBs).

For example, rapid prototyping can save money in the future by detecting errors in the PCB design, such as wrong positioning of components or short circuits, early enough when fabricating the board.

Advantages of Rapid Prototyping for PCB Solutions

- Risk Reduction: Rapid prototyping enhances early detection and solving of design defects, reducing chances of failure in the end product.

- Cost Efficiency: Companies can avoid costly revisions during the full production phase by pointing out and rectifying issues earlier on.

- Faster Turnaround: Speeding up the design process means quicker iterations and shorter time to market that maintains a competitive edge.

- Improved Accuracy: Prototypes accurately represent the final product, thus ensuring high accuracy in meeting design specifications.

- Enhanced Communication: A tangible prototype makes communication clearer among team members and stakeholders and aligns expectations.

- Customization Opportunities: It is easier to include custom requirements and changes specific to the needs of large enterprises by using rapid prototyping techniques.

- User Testing: Testing prototypes with real users can be valuable for improving the PCB design.

- Material Testing: Various materials and components may be tested in the prototype to determine the most suitable for the final product.

Rapid Prototyping Technologies for PCBs

3D Printing

3D printing is also known as additive manufacturing and is nearly like a magical stick that produces prototypes of PCBs.

With this technology, you can stack and layer materials to create specific sections or even the entire board. It’s quick, economical, and highly flexible for comprehensive PCB design Solutions.

You can experiment with intricate sizes and shapes without any worries, but if it’s not perfect, just print another one!

CNC Machining

is all about accuracy. This means using computers to control machine tools that chip away at solid material until your PCB comes out. You can liken this system to shaping up your board from a mass with mechanical precision.

When you need your prototype to be tough as nails with those minute details that are hard to get.

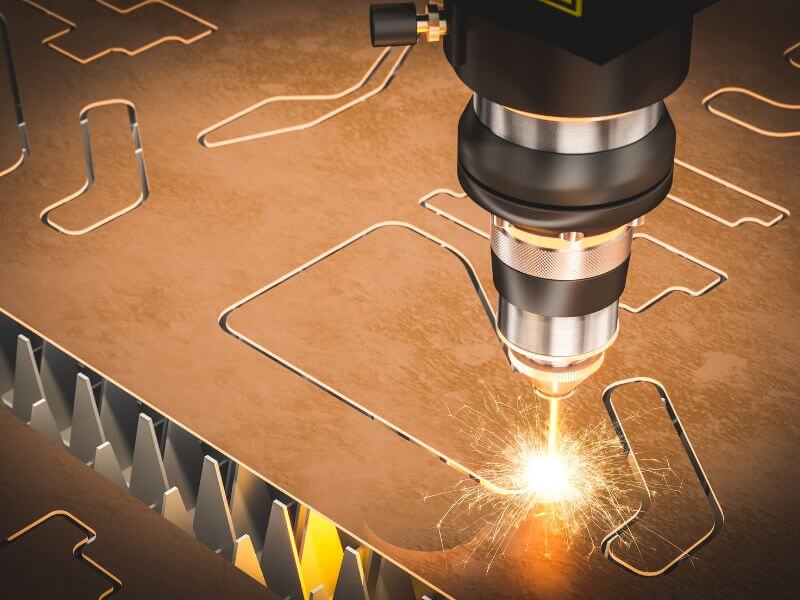

Laser Cutting

Using lasers to cut things, laser cutting is the way to go when making PCB prototypes that are really cool.

These concentrated beams of light slice through materials with absolute precision. For instance, this facilitates cutting out complicated shapes or etching very fine details on the boards; hence, it has speed and gives smooth edges.

Advanced PCB Fabrication Techniques

Then there are the high-tech ones, such as advanced PCB fabrication techniques and high-density interconnect (HDI), which lets you squeeze more stuff in less space without compromising signal integrity at all.

It’s like having an entire apartment inside one room but still feeling uncrowded! Smaller, faster & more efficient PCB designs make these methods possible; they provide greater functions, thus allowing for much less power consumption during use.

Applications in Large Enterprises

Rapid prototyping for PCBs could greatly benefit large corporations, leading to major advances in their operations and product ranges. The following are key fields where these applications may be found:

- Aerospace and Aviation: Custom PCBs are used to develop and test high-reliability avionics, navigation systems, and communication equipment.

- Automotive Industry: Rapid prototyping accelerates the development of automotive electronics, including engine control units (ECUs), infotainment systems, and safety features.

- Medical Equipment: Medical devices require precision and reliability; thus, prototyping is involved in creating PCBs for imaging machines, patient monitoring systems, and diagnostic devices.

- Consumer Electronics: Quick prototyping is indispensable in the iterative design processes for smartphones, wearables, and home gadgets since companies keep updating their products.

- Telecommunications: Prototypes help develop complex boards such as those used in networking infrastructure, antennas, and switching systems that support faster communications.

- Defense and Military: Examples of prototypes utilized by defense include custom PCB prototypes for secure communication equipment or control systems, among other sophisticated weaponry.

- Industrial Automation: Smart factories use rapid PCB prototyping to develop sensors, control systems, and robotics.

Frequently Asked Questions About Rapid Prototyping for PCB Solutions

What is the basic function of rapid prototyping in PCB design?

Rapid prototyping in PCB design aims to create and try working models as quickly as possible. During this time, engineers and designers can test the feasibility of a design and board functionality and spot any potential problems early on.

How does 3D printing help in PCB prototyping?

The utilization of a 3D printer makes it easier to print complex PCB designs at a lower cost within a short period and then be able to test them for form, fit, and function.

Therefore, designers can use different layouts or component placements without worrying about expensive tooling because it is flexible enough.

Can rapid prototyping be employed for the mass production of PCBs?

Rapid prototyping generally aims to test designs, but lessons learned from this phase, such as refinements, can be used to simplify mass production.

Actually, mass production methodology may vary from that used in rapid prototyping techniques due to scalability and cost-effectiveness issues.

Which is better for prototype development – CNC machining or laser cutting when making printed circuit boards?

It depends on the specific requirements for a given PCB design. For instance, laser cutting allows for fast manufacturing with clean edges suitable for complicated shapes, while CNC machining ensures strong, robust prototypes with fine details.

Various factors determine the most suitable, including material type, complexity of design, and desired precision levels for the prototype.

Can user testing be integrated effectively during the rapid prototyping phase for PCBs?

Incorporation of user testing into the process of rapid prototyping has great benefits. When feedback from actual users is integrated into their PCB designs, these finished products become friendlier and more efficient.

TTRD – Your Reliable Partner in Rapid Prototyping Customized PCB Solutions

Our goal at TTRD is to provide unmatched B2B services and build strong partnerships in custom PCB prototyping. We also offer a comprehensive and flexible integrated manufacturing and OEM / ODM service for Demanding Environments

With our team’s extensive experience and skill, we can deliver you Unparalleled Expertise in PCB assembling and technical knowledge.

TTRD’s fast prototyping capabilities are one of our key objectives in helping you stay ahead of the competition.

Get in touch with us today for more information about your custom PCB prototyping requirements and how our TTRD team can assist in expediting your product development process.